MLF- The Product

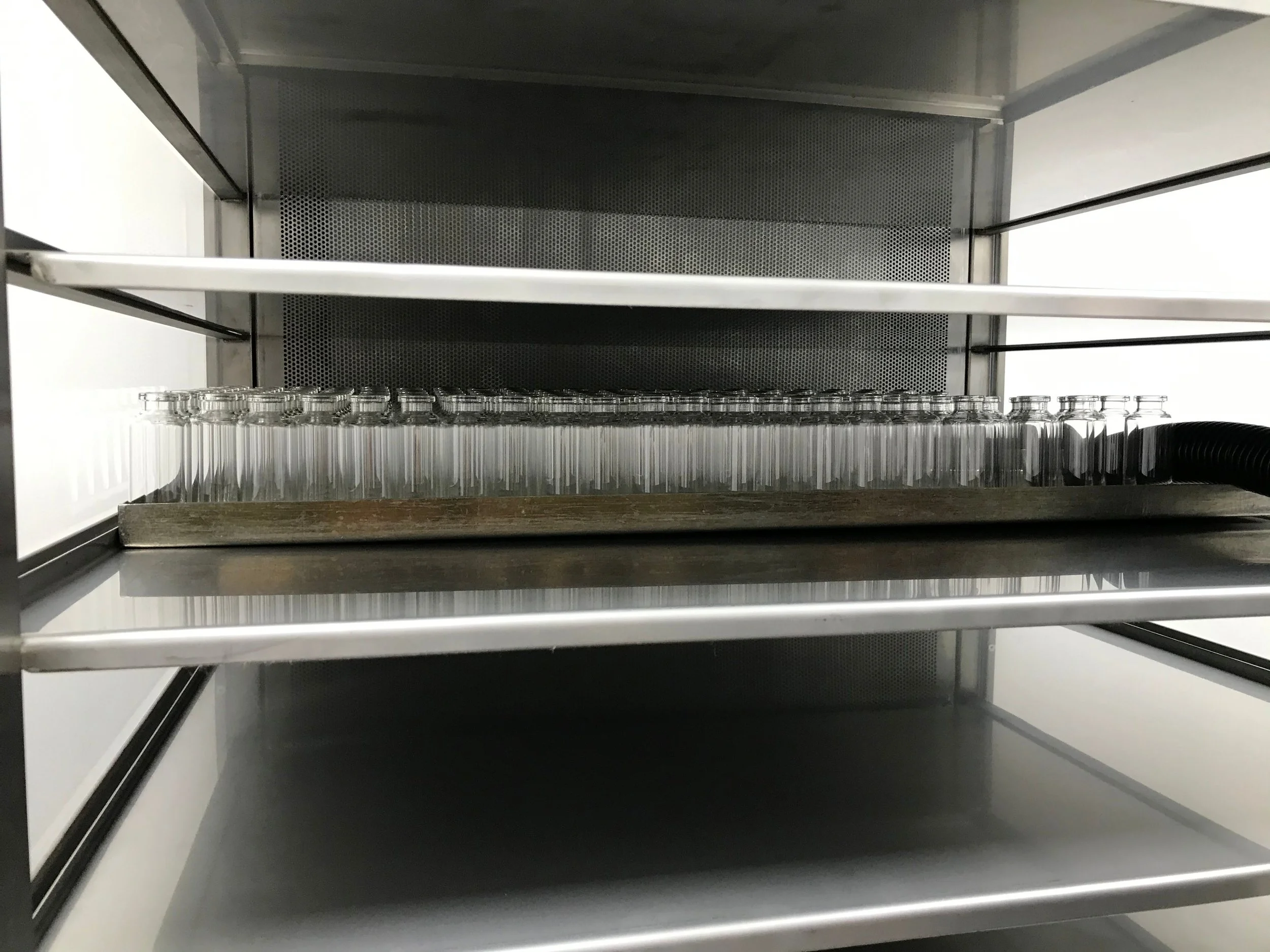

The idea for these mobile laminar flow cabinets was born from a critical need at a pharmaceutical lab: the secure and sterile transfer of a highly sensitive drug from one cleanroom to another, through non-classified spaces. The alternative options at the time were either a costly and time-consuming redesign of the entire facility layout, or to develop a mobile solution—a theoretical idea that we gradually transformed into a functional reality.

The core objective was to build a mobile unit capable of maintaining sterile and contaminant-free conditions, even when moved through uncontrolled environments.

Key Development Milestones:

After extensive research, testing, and refinement, we successfully built the first cart.

One of the main technical challenges was autonomy. The unit had to run on batteries without being plugged in during use, requiring a continuous operating time of 2 to 3 hours.

Over the past 20 years, the carts have been improved and customized to fit each client’s specific needs—adjusting dimensions, battery capacity, shelf quantity, and more.

Notable Achievements:

In 2018 and 2019, we sold six units to Zoetis, a leading pharmaceutical lab in Brazil. The design phase included numerous consultations and audits.

Final testing and calibration were overseen by an independent, respected third-party agency that verified compliance and issued operational certification.

U.S. Market Goals:

Although the product has proven highly successful and innovative, we have yet to fully invest in marketing and promotion. The technology remains relatively unknown,

and our main objective in the U.S. is to introduce and position it in the market as a versatile solution for pharmaceutical, biotech, food, and other industries requiring controlled environments.

We have already started building relationships with U.S.-based production and testing partners and intend to expand this network further.

We aim to:

Showcase the cart at trade shows focused on pharma, biotech, and cleanroom technologies.

Build brand awareness and credibility through strategic marketing.

Engage potential buyers and distributors in key industrial sectors.

Next Steps

We currently have a completed unit in Argentina, built with our trusted local supplier, which we plan to import to the U.S. for demonstration purposes.

We are pursuing U.S. patent registration, as the product is currently patented only in Argentina.

We are actively searching for U.S. suppliers and manufacturers to support local production. For now, we will continue offering custom-built units, as our experience shows each client requires tailored specifications.

We are working on identifying and engaging with potential clients to begin quoting and selling the product in the U.S. market.

Technical Notes

Our mobile laminar flow cart integrates high-quality components, many of which are sourced directly from the U.S., including:

Dwyer Magnehelic pressure gauges

UPS systems and batteries

Electrical plates

Fans

Hygienic wheels

HEPA filters

Entire structure built with AISI 304 stainless steel.